Automatic filling machine hand sanitizer liquid soap shampoo filler

- Suitable material: Oil, jams, daily chemicals, hand sanitizer, hand wash, rinse free hand sanitizer, disinfectant ,shampoo, shower gel ,body wash, conditioner .

- This filling machine is a high-tech filling equipment controlled by

microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action. - Accurate measurement: adopt servo control system, ensure the

piston can always reaches constant position. - When close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution.

- Convenient adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment.

Details About Automatic filling machine hand sanitizer liquid soap shampoo filler

Filling Equipment Specifics

If you want to switch over your operations in order to make hand sanitizer during these times, these are the technical details you need to know:

The best way to bottle the sanitizer is with an automatic piston filler or pressure gravity filler. However, because the product is flammable, the filler must have explosion proof controls, which will cause production to take longer.

If you need a faster output, you can fill with a sami-automatic piston filler. Your production speeds will be slower, but because the sami-automatic piston filler is fully pneumatic, no explosion-proof controls will be needed.

It’s not easy, but manufacturers who can transition to making hand sanitizer will find a high demand market.

Festa Machine offers all of our clients customized solutions to your filling needs.

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

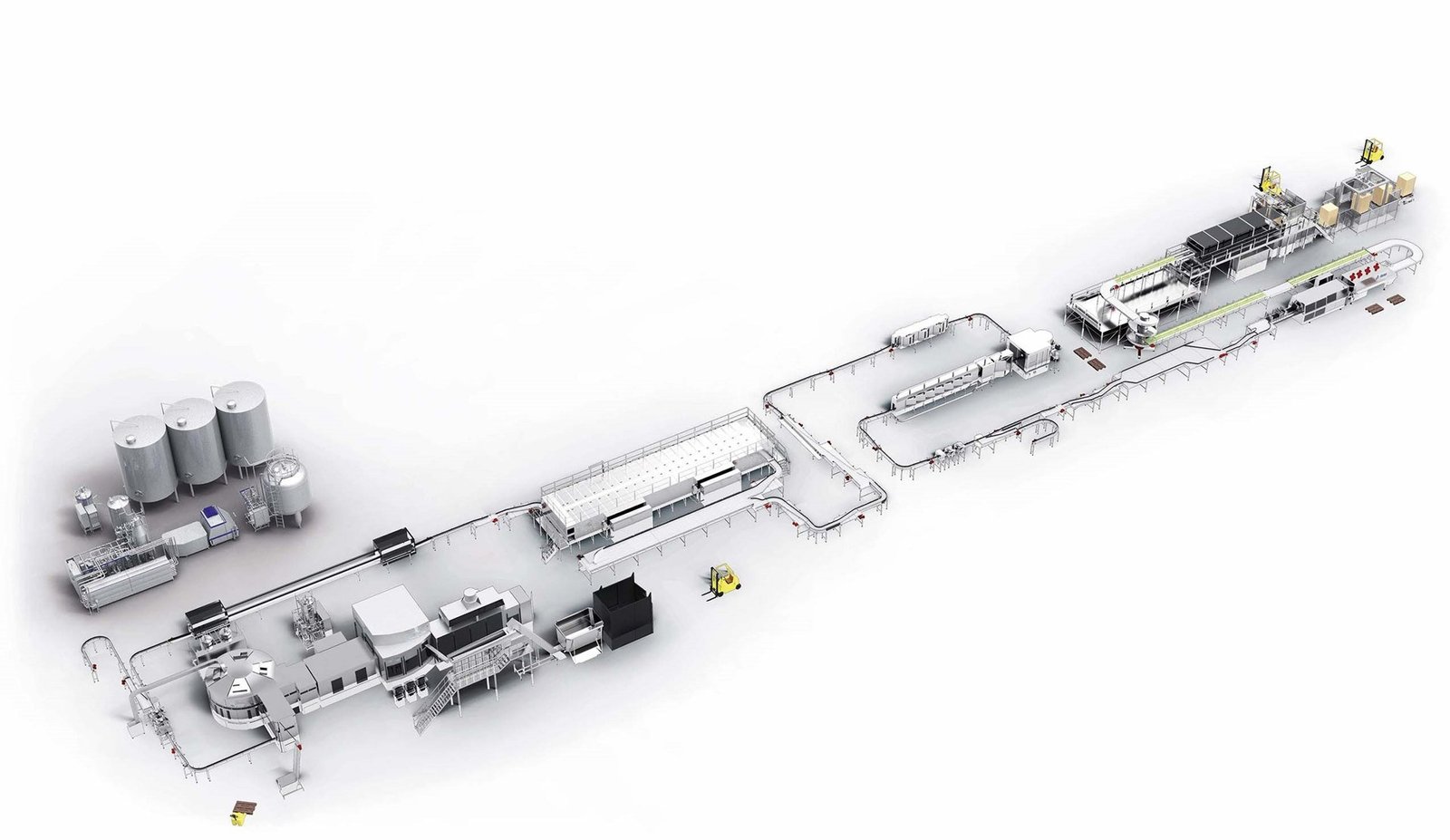

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.