Carbonation Machine & Carbonator Manufacturer in China

- Professional customization: design our machine according to your liquid parameters.

- High quality accessories: we cooperate with Siemens, Mitsubishi, Festo, etc.

- Fast delivery: usually we only need 35 working days to have the delivery conditions.

Custom Industrial Carbonator for Your Beer & CSD Plant.

Festa drink carbonation machine is a new type of mixer developed by ourselves on the basis of introducing advanced technology from Germany. This machine has the advantages of reasonable structure, advanced process, high mixing precision, sufficient mixing of carbon dioxide, convenient operation, and has a wide range of applications. It can be used in the production of beer, carbonated drinks, wine and fizzy water,sparkling water, etc.

DBCH5 Soda Carbonation Machine

Our soda carbonation machine capacity ranges from 3,000 liters per hour to 25 tons per hour. This machine is our small industrial carbonators, widely welcomed by the market, is used in the production of carbonated beverages processing machine.

- Production Capacity: 5,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 2400X1500X2000mm

DBCH8 Drink Carbonation Machine

DBCH8 is the best carbon dioxide mixer we sell, and it can be used with 12000BPH (500ml) carbonated beverage filling machine. Fully automatic operation, gravity mixing, high processing capacity.

- Production Capacity: 8,000 liters per hour

- Gas Volume: ≥2.5

- Dimension:2700X1535X2100mm

DBC10 CO2 Carbonation Mixer

FESTA DBC10 co2 carbonation mixer is used for middle capacity soft drink bottling plant, can work with 18000BPH(500ml) carbonated soft drink filling line. The mixing ratio of sugar, water and carbon dioxide can be precisely controlled.

- Production Capacity: 10,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 2950X1650X2150mm

DBC15 Beverage Carbonation Machine

When the customer’s CSD filling line capacity is in 24000BPH (500ml), you can consider purchasing FESTA DBC15 automatic carbonator. Can produce 12-15 tons of carbonated beverage per hour.

- Production Capacity: 15,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 3050X1700X2200mm

DBC18 Sparkling Water Carbonation Equipment

FESTA DBC18 carbonation mixer is usually used with 32000BPH (500ml) high-speed sparkling water filling monoblock. It is also suitable for the production of other carbonated drinks.

- Production Capacity: 18,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 3200X1900X2250mm

DBC25 Industrial Carbonation Machine

It can produce 24,000 liters carbonated drink per hour and can be paired with ultra-high-speed 48000BPH soft drink production line. The machine is assembled with the most advanced components and the highest precision parts.

- Production Capacity: 25,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 4000X2400X2580mm

YHZ25 Liquor & Beverage Carbonation Machine

YHZ series carbon dioxide mixer is an advanced on-line automatic mass flow mixer, which can automatically detect and accurately adjust the mixed sugar content, which can minimize the blending accuracy error caused by the traditional manual blending syrup and save the cost of the blending system.

- Production Capacity: 25,000 liters per hour

- Gas Volume: ≥2.5

- Dimension: 4100X2380X2600mm

Related Equipment of Carbonated Soft Drink Production Line

FESTA Offers a Variety of Beverage Carbonation Mixer Systems.

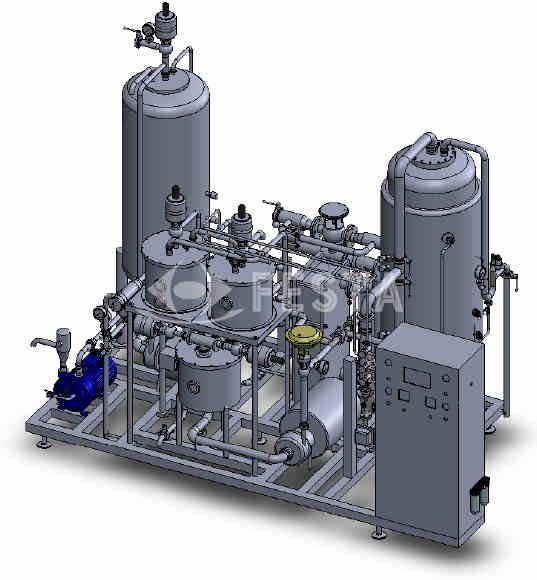

According to the budget and product characteristics of different customers, we provide single-tank carbonation mixer, three-tank carbonator machine, traditional 5-tank drink carbonation machine and flowmeter type carbonated mixing system. If customers require low energy consumption when producing carbonated beverage, we have also developed a ambient temperature carbonation equipment. In FESTA, you can get all solutions for your CSD plant.

High Gas Volume of FESTA Carbonator.

Carbonated drinks and beer need to be mixed with carbon dioxide before filling, and our fully automatic high-speed carbonated mixer can reach a gas volume of up to 4.2. The CSD and beer produced in this way will have rich bubbles and unique taste. Gas volume can be adjusted according to different products, ranging from 2.5 to 4.2.

Can be Connected to CIP System for Automatic Cleaning

The whole machine has designed a complete circulation pipeline, using corrosion-resistant seals, which can be cleaned by CIP, and can be cleaned and disinfected with hot water or other chemical cleaning solution to avoid sanitary dead corners.

FESTA CSD Filling Line with Carbonation Machine

Generally speaking, carbonation machine is usually an important part of the CSD production line, the mixing effect determines the efficiency of the whole production line, and will have a good impact on the final product.

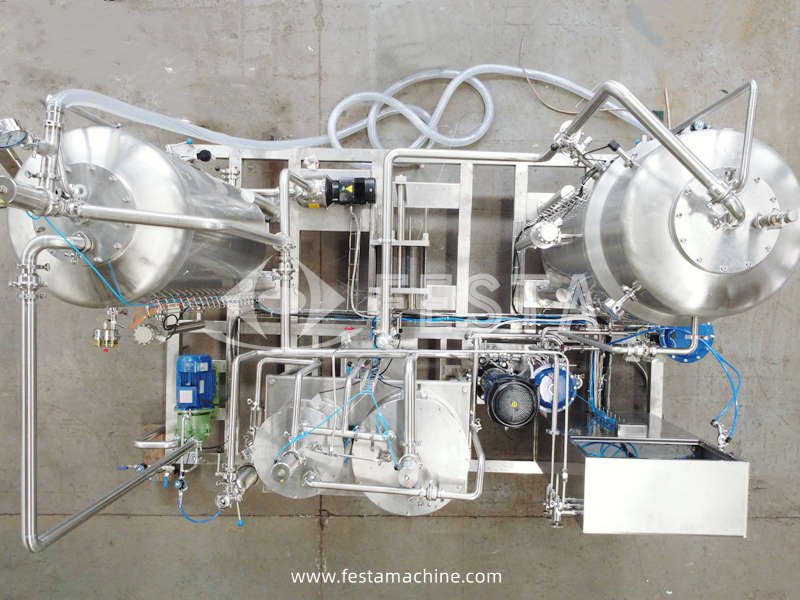

Visit Our Factory to See More

We based in China, we have a big factory to produce industrial carbonator

The Ultimate Buying Guide for Drink Carbonation Machine

Drink carbonation machine, we also call it drink carbonator or carbonation mixer, it is an indispensable important equipment for the production of soda and sparkling wine. The fruit juices, drinks and water we drink every day are non-carbonated, but if we want to enjoy carbonated drinks, we need drink carbonation machine to complete the carbonation process. It mixes CO2 gas into the beverage through a special process.

As the pH of carbonated drinks and sparkling wine is acidic, we use stainless steel 304 as the main material of the whole machine and stainless steel 316 in contact with liquid. The water pump and syrup mixed pump adopt the model of high hygiene level to ensure the safety of the product.

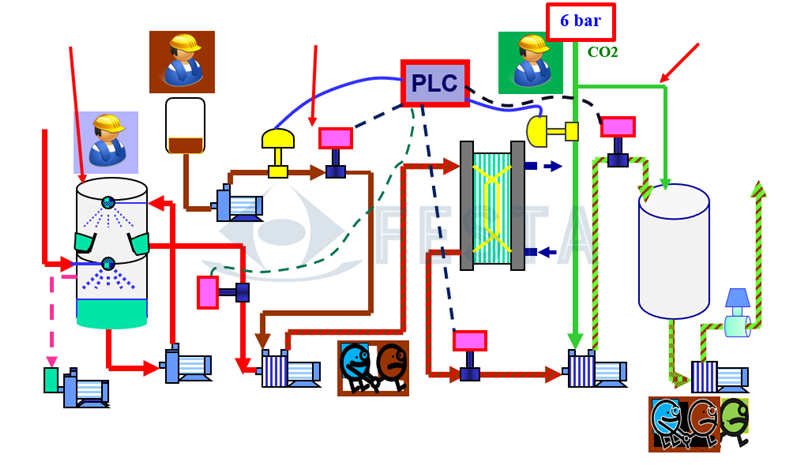

The machine is mainly composed of de-aerator system, mixing system, pre-carbonization system, cooling system, carbonization system, control system and frame.

1) De-aerator system-this system uses vacuum pump to vacuum the degassing tank, and the treated water removes the gas in the treated water under the condition of high vacuum, so as to achieve the purpose of stable filling.

2) Mixing system-the treated water without gas and the cooled syrup are accurately mixed under the CO2 gas pressure drop, the liquid level in the water tank and syrup tank in the mixing system is accurately controlled by the buoy device, and the liquid level in the mixing tank is accurately adjusted by the regulating valve to achieve a stable mass flow.

3) Pre-carbonization system-CO2 gas is quantitatively injected into the mixed beverage through the CO2 metering device.

4) Cooling system-this system mainly cools the mixed drinks to the optimal carbonation temperature.

5) Carbonation system-the beverage after pre-carbonization and cooling treatment is finally carbonated to the expected air content.

6) Control cabinet and rack-equipped with PLC, electric switch, pneumatic device, including all air valves, air switch, relay, Flowmeter control device, touch display screen.

Stainless steel rack on which most equipment components are mounted. The frame is of welded construction with adjustable stainless steel legs and stainless steel backing plates.

1) Wide range of uses-the system can handle many kinds of products, such as carbonated drinks, fruit juice drinks and so on.

2) Accurate carbonation mixing accuracy-product mixing accuracy G ≤ 2%.

3) Power adjustment is easy-the carbonation ratio can be easily adjusted without replacing parts.

4) Structural hygiene-all parts in contact with fluid are made of high quality stainless steel, all tanks are equipped with CIP spray balls for easy cleaning, water tanks, syrup tanks and mixing tanks are all sealed, the head is usually filled with CO2 gas or other clean gases, and the liquid will not be polluted by the atmosphere.

5) CIP cleaning and hot water disinfection can be carried out-the equipment is composed of heat-resistant parts and can be cleaned and disinfected with hot water and other chemical solutions.

Only carbonation machine for beer and carbonated beverages is involved here.

The first is the traditional gravity mechanical carbonation mixer, which has the advantages of simple structure, low cost and high carbonation rate.

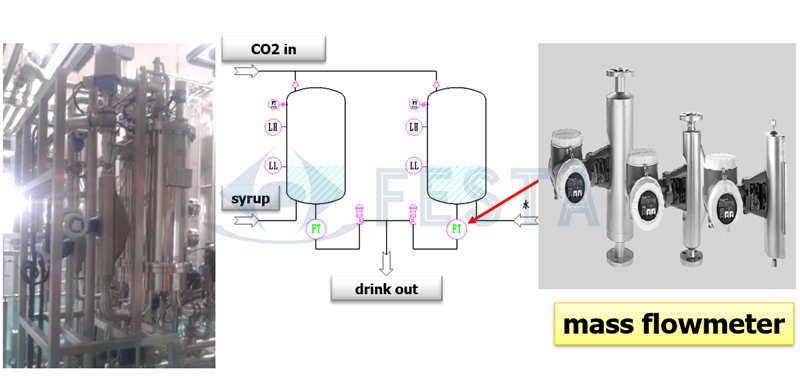

The second is the new Flowmeter carbonation machine, which is an advanced on-line automatic mass flow mixer, which can automatically detect and accurately adjust the mixed sugar content.

1) Stable carbonization accuracy: the mass flowmeter is used to detect the material flow and carbon dioxide mixing flow, and the control valve is controlled to ensure the mixed flow of liquid and carbon dioxide, realizing the on-line adjustment of gas volume and step-less adjustment within a given range. At the same time, the system sets the pressure of the finished product tank according to the gas volume of the carbonated beverage and the operating conditions of the downstream CSD filling equipment to maintain the stability of the gas volume.

2) Efficient vacuum de-aerator system: this system is the core unit of the carbonation mixer, which removes oxygen and other gases from the process water from the beverage by spraying in a vacuum environment.

3) Automatic CIP cleaning can be carried out.

De-aerator is the removal of O2 or other insoluble gases from the water.

Purpose: Facilitate carbonation and reduce foaming during perfusion.

Vacuum degassing is based on the formation of vacuum conditions in the degassing tank.

Vacuum degassing is based on the formation of vacuum conditions in the degassing tank.

The water to be degassed is sprayed into the degassing tank through the nozzle.

O2 and N2 are removed from the degassing tank due to vacuum action.

The selection of a suitable spray system will ensure that the water droplets produced will be as small as possible, so there will be a larger contact area in the degassing process.

Mixing ratio system: mixing ratio system is a mixing machine.

The main function of the core part of the mixer is to mix water and syrup in a certain proportion.

At present, there are generally three ways of mixed ratio system.

Gravity feed liquid mixing ratio system.

Electronic Flowmeter control mixing system.