Reverse Osmosis water treatment plant system (Purified Water)

Reverse Osmosis water treatment system. The main equipment are silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc. The treatment capacity is 0.5-50 ton/hour. It can effectively get rid of muddy organic matter, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of microorganism and some of heavy metal ion in the water, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water.

Details About Reverse Osmosis water treatment plant system (Purified Water)

Reverse Osmosis Machine System.The main equipment ofare silica sand filter, active carbon filter, sodium ion exchanger, hollow fiber, RO( reverse osmosis), UV sterilizer, precision filter, ozone generator, water tank etc. The treatment capacity is 0.5-50 ton/hour. It can effectively get rid of muddy organic matter, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of microorganism and some of heavy metal ion in the water, reduce the hardness of the water to make all specifications of the water quality fully meet the state fresh water standard of fresh drink water.

First stage pretreatment.(Sand filter)

The use of multi-medium quartz sand filters, main purpose is to remove the water contains sediment, manganese, rust, colloid material, mechanical impurities, suspended solids and other particles in the above 20UM of substances hazardous to health. The effluent turbidity is less than 0.5NTU, CODMN less than 1.5mg / L, iron content of less than 0.05mg / L, SDI less than or equal to 5. Water filter is a kind of “physical – chemical” process, the water through granular materials when isolated filter water impurities and colloidal suspensions. Filter is an effective water purification and treatment of the main process in the preparation of pure water is an indispensable process.

Second stage pretreatment (Carbon filter)

Activated carbon filters used to remove the pigment in the water, smell, a large number of chemical and biological organisms, reducing the residual value of water and pesticide pollution and other harmful pollutants. The structure of activated carbon filters and quartz sand filters, the difference is placed inside the strong adsorption capacity of activated carbon for removal by the quartz sand filter without the filter out organic material, adsorption of residual chlorine in the water, using water more than less than or equal to chlorine 0.1ML/M3, SDI less than or equal to 4, are strong oxidants chlorine, there are various types of membrane damage, in particular, reverse osmosis membranes are more sensitive to chlorine. In addition, the activation process, the surface of activated carbon to form non-crystalline parts of some oxygen-containing functional groups, these functional groups can have a chemical adsorption of activated carbon catalytic oxidation of bad news, to restore the performance, can effectively remove a number of metal ions in water.

Third stage pretreatment (Resin softener)

Cationic resin used for water softening, primarily to remove hardness of water. The hardness of water is a major calcium (Ca2 +), magnesium (Mg2 +) ion composition, when containing the raw water hardness ions through the resin layer, the water of the Ca2 +, Mg2 + was exchanged resin adsorption, and other objects at the same time the quality of the release of sodium Na + ions flow from the softener in the water is removed from the softened water hardness ions. So as to effectively prevent the reverse osmosis membrane fouling.System can automatically recoil, and so is red.

Fourth stage pretreatment (Micron filter)

Particle size in water to remove fine particles, sand filters can remove very small colloidal particles in the water, so that the turbidity reached 1 degree, but still per milliliter of water for hundreds of thousands of particle size 1-5 microns colloidal particles, the pressure on this filter to remove water after the particle size of 100 microns or less in small particles, to further reduce the turbidity, to meet the next process of the water requirements of the protection of the next long-running processes.

RO system

Using reverse osmosis technology for desalination, reverse osmosis membrane was only 0.001 micron pore size, can be harmful to remove dissolved solids and bacteria, viruses, etc., desalination rate of more than 99.6 percent, in line with national standards to produce pure water, the host section contains the security filter, high-pressure pump and reverse osmosis membrane, security filters for the fourth

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

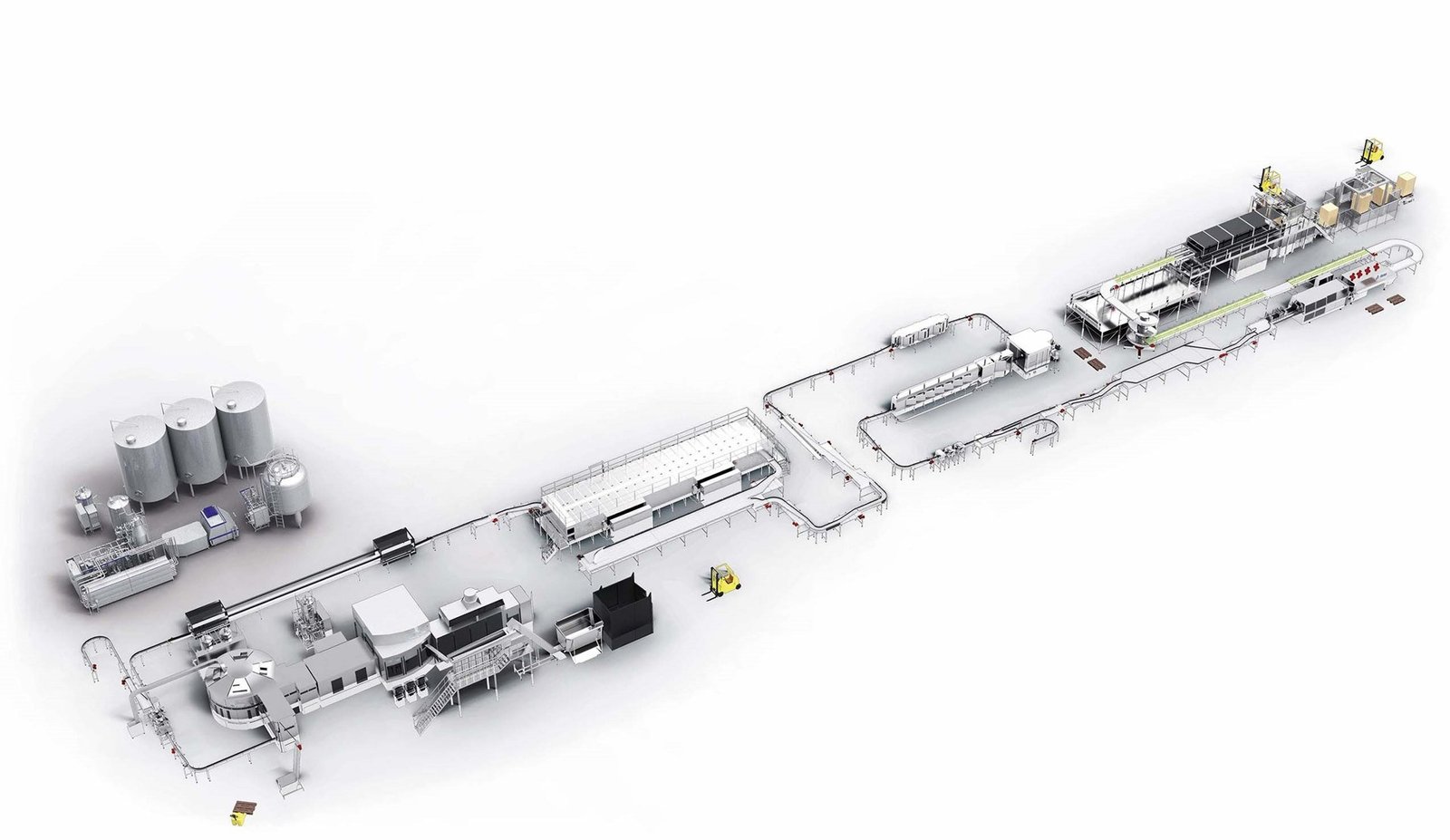

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.