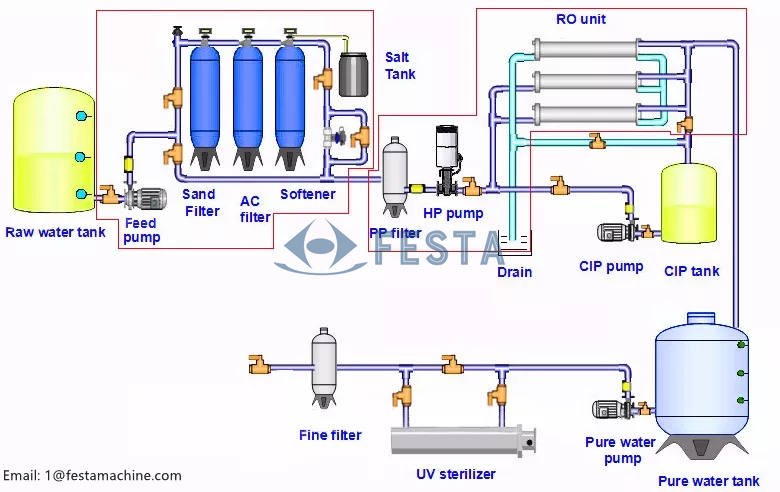

Raw water→Raw Water Tank→Raw Water pump→Quartz Sand Filter→Activated Carbon Filter→Fully Automatic Softening Water Equipment→Precision filter→Reverse Osmosis System→Ozone Sterilizing System/UV Sterilizing System→Pure Water Tank→Water Consumption Point

1. Raw Water Tank

The device prevents the booster pump from directly drawing water from the pipe network due to insufficient flow and unstable pressure, which may damage the booster pump or affect the normal operation of the system. The original water tank has built-in stainless steel floating ball valve and liquid level sensor. Large equipment shall be equipped with water intake electric disc valve

1) The function of floating ball valve is to control the inflow of raw water and replenish water in time when the system is running.

2) The liquid level sensor has middle water level and low water level, and its function is to control the start and stop of the booster pump; when the water level of the water tank is above the middle water level, the booster pump can start automatically; when the water level of the water tank is lower than the low water level, the booster pump will stop automatically.

2.Raw Water Pump

In order to ensure the constant flow and pressure of the system water supply, the system raw water booster pump import brand: Denmark Granford, Germany Wheeler, Spain Asba, maintenance-free mechanical seal pump, high efficiency, low noise, stable and reliable performance. Or choose China’s well-known brands: CNP pump, Wuxi Jiuyang pump.

The original water pump is automatically started and stopped by the water level of the original water tank.

3.Coagulant Dosing Device

Commonly used dosing pumps are: American Milton, American Pasfeida.

Coagulation-the use of iron salts, aluminum salts, polymers and other coagulants, through flocculation and bridging interaction with impurities in water to form large particle precipitates, and then through other equipment, such as clarification, filtration, etc., to remove.

Add appropriate amount of coagulant, effectively coagulate colloids and organic impurities in water, make the above substances form large particle precipitates or flocs through flocculation and bridging action, and then go through pretreatment and filtration to improve the filtration effect of pretreatment, and the SDI (pollution index) after treatment is less than 5.

If the influent SDI value is too large, it is necessary to add coagulant aids.

Commonly used coagulants are: aluminum sulfate, polyaluminum chloride, ferrous sulfate, ferric chloride and so on.

Commonly used coagulation aids are: calcium oxide, calcium hydroxide, polyacrylamide, sodium carbonate and so on.

Control: start synchronously with the original pump.

4.Pre-treatment

At present, we often have three kinds of pretreated filters: stainless steel filter, FRP filter and carbon steel lined rubber filter.

The pretreatment filtration is divided into three parts: multi-media filtration, iron and manganese removal device, activated carbon filtration and softening filtration; the American Artuzu multi-way valve can be used to automatically control the backwashing and positive washing of the filter material in the filter tank according to the set time; or choose manual operation control.

The preliminary treatment of water before refining treatment, in order to achieve good results in the refined treatment of water and improve the quality of water.

Because there are a large number of impurities in natural water, such as sediment, clay, organic matter, microorganisms, mechanical impurities and so on, the existence of these impurities seriously affects the quality and treatment effect of refined water. Therefore, some impurities must be reduced or removed before refining, which requires pretreatment.

1)Multi-media Filter

Multi-media filter is mainly used to remove suspended matter, sediment and particulate impurities in water.

The main fillers are: quartz sand, anthracite, fiber ball and so on.

2)Iron Removal Filter

The influent iron ion requirement of RO: Fe2+ ≤ 0.1mg/L, sometimes it can be relaxed to ≤ 1mg/L in order to save cost.

Its main filler is natural manganese sand.

Principle of iron removal: oxidation method is used to oxidize low-valent iron ions and low-valent manganese ions in water to high-valent iron ions and high-valent manganese ions.

3)Activated Carbon Filter

The activated carbon filter is equipped with granular water purification activated carbon, which mainly removes macromolecular organic matter, colloid, odor, residual chlorine and other impurities in the water, and has strong decay absorption, with an average removal rate of more than 90%.

Among them, the residual chlorine is a strong oxidant, which can oxidize the Ro film, which must be limited to ≤ 0.1mg/L.

There are three kinds of activated carbon: round strip carbon, amorphous fruit shell carbon and coconut shell carbon.

4)Cationic Resin Softener

The principle of sodium ion exchange softening treatment: the raw water is passed through the sodium cation exchange resin, and the hardness components Ca2+ and Mg2+ in the water are exchanged with the Na2+ ions in the resin, thus absorbing Ca2+ and Mg2+, in the water to soften the water.

Function: it is of positive significance to prevent the fouling on the surface of reverse osmosis membrane and improve the working life and treatment effect of reverse osmosis, so the softener is not needed when the total hardness is less than 200mg / L CaCO3.

The best control mode is automatic control.

5.Scale Inhibitor Dosing Device

1. Colloidal particles are surrounded by anionic or Nonionic polymers to stabilize them in a dispersed state, which are called dispersants.

For example, phosphate.

2. Turn metal ions into a chelating ion or complex and ion, which inhibits them from combining with anions to form precipitates. These agents are called chelating agents and complexing agents.

Such as: EDTA.

(3) using the coagulation and bridging effect of polymer coagulant, the colloidal particles are formed into alum flowers and suspended in water.

For example, polyacrylamide.

The main function of the device is to prevent the reverse osmosis membrane from fouling, and the American metering pump is used to add the medicament, the dosage is accurate and the stability of the equipment is good.

Commonly used dosing pumps are: American Milton, American Pasfeida.

Commonly used scale inhibitors are: sodium hexametaphosphate, organic phosphate, polypropylate.

Control: synchronous start of the same stage high pressure pump

6.Precision Filter

The main purpose of the device is to fine filter the inlet water of the reverse osmosis system, and the purpose is to reduce or eliminate the broken particles of the filter material leaked from the pretreatment equipment to play the final protective role, so as to ensure that the water finally entering the reverse osmosis system meets the requirements.

Filtering accuracy: generally 10um, 5um, 1um

7.Pressure Control Switch

Control the start and stop of the high-pressure pump to prevent the high-pressure pump from running under the condition of lack of water and insufficient water supply, and guide the damage of the high-pressure pump.

Generally, the inlet pressure of the high-pressure pump can only be started automatically when the inlet pressure is greater than 1kg, and stop automatically when it is less than 0.5kg.

8.High Pressure Pump

Apply constant pressure to the anti-penetration system.

Control: the water level of the original water tank, the pressure switch, the regenerative fretting switch and the water level of the pure water tank are used to control the automatic start and stop.

9.Water Intake Solenoid Valve

The main functions of the device are as follows: when the pure water tank is full or the automatic head is backwashed and regenerated, the system automatically controls the electromagnetic shutdown to realize the automatic stop of the system.

10.Reverse Osmosis Device

1) Working Principle:

Osmosis-when two solutions of different concentrations are separated by a semi-permeable membrane, the solvent in the dilute solution will pass through the semi-permeable membrane into the concentrated solution.

Reverse osmosis is a scientific method to reverse its natural osmosis process. When an external pressure is greater than the osmotic pressure on one side of the concentrated solution, the solvent will reverse its original osmosis direction and enter the dilute solution through the semi-permeable membrane on the side of the concentrated solution.

2) Influent requirements: turbidity ≤ 2 degrees water temperature: 5-35 ℃ SDI ≤ 5 Fe ≤ 0.1mg/L.

PH:4-11 residual chlorine ≤ 0.1mg/L.

3) The system can use the most advanced American Dow membrane element, American Hyde energy membrane element, Japanese Toray membrane element and Shihan membrane element as the main components, the desalination rate of single root membrane is ≥ 99%, and the desalination rate of the system is 97-99%, and can effectively remove suspended solids, organic colloids, organic matter, bacteria, viruses, heat sources and other impurities in water, in order to ensure the stable performance and long-term operation of the RO device.

A Timing automatic flushing device is set up.

4) At present, the working pressures of RO used in our country are: ultra-low pressure membrane-7-10kg, low pressure film-15kg, high pressure film-55kg.

5) Membrane material: the commonly used membrane is full-aromatic polyamide composite membrane with high cross-linking degree (abbreviated as: polyamide composite film).

The less commonly used membrane is cellulose acetate membrane.

6) Commonly used brand membrane code:

Dow: BW30-4040 represents brackish water desalination film-4 inches in diameter and 40 inches in length, working pressure 15kg.

TW30-4040 means ordinary municipal water film-4 inches in diameter and 40 inches in length, working pressure 10kg.

BW30-400 represents brackish water desalination film-effective area 400sq ft, working pressure 15kg.

SW30 series represents seawater desalination film, working pressure 55kg.

Hydranautics: ESPA series represents ultra-low pressure high flux membrane, working pressure 10kg, in which ESPA4 is 7kg.

CPA series represents brackish water desalination film, working pressure 15kg.

SWC series indicates seawater desalination film, working pressure 55kg.

Shihan: BE4040 (8040)-BE series indicates high desalination rate membrane, working pressure 15kg.

BE4040 (8040)-BL series represents ultra-low pressure high flux film, working pressure 10kg.

Toray: TM series means low pressure high flux film, working pressure 16kg.

TMG series represents ultra-low pressure high flux film, working pressure 7.5kg

11.First-class Pure Water Intermediate Tank (also known as intermediate water tank)

The function of the intermediate water tank is to control the operation of the booster pump, the first-stage high-pressure pump and the second-stage high-pressure pump, stop and ensure the water supply to the two-stage high-pressure pump, prevent the two-stage high-pressure pump from running under the condition of lack of water, and guide the damage of the two-stage high-pressure pump.

There are high, medium and low water levels in the middle water tank.

The two-stage high-pressure pump automatically stops operation when the water level of the water tank is low, and can not start automatically until the water level of the water tank reaches or is higher than the middle water level; when the water level of the water tank is lower than the middle water level, the booster pump and the first-stage high-pressure pump automatically start to make water, until the water tank is high, the booster pump and the first-stage high-pressure pump stop automatically.

12.Two-stage Caustic Soda Unit

If the device is set up to add an appropriate amount of N an OH (sodium hydroxide), the carbon dioxide and the monomolecular chemical reaction through the RO membrane will form a molecular mass to better remove the secondary ions, so as to improve the secondary water production effect.

Generally, the conductance of secondary water can reach less than 2us / cm ², and if properly adjusted, it can also reach less than 1 us / cm ².

Control: start synchronously with the secondary high pressure pump.

13.Ozone Sterilization System

Bactericidal mechanism: the bactericidal effect is realized by destroying the structure of microbial membrane by oxidation.

Ozone first acts on the cell membrane, causing damage to the components of the membrane, resulting in metabolic disorders. Ozone continues to penetrate the membrane, destroying lipoproteins and lipopolysaccharides, changing cell permeability, leading to cell dissolution and death.

On the other hand, ozone inactivates the virus by directly destroying its ribonucleic acid RNA or deoxyribonucleic acid DNA substance.

The ozone sterilization system consists of an ozone machine and an ozone mixer. The ozone mixer fully mixes the ozone produced by the ozone mechanism with the finished water, which can sterilize the bacteria remaining in the finished water.

Ozone machine is equipped with 3 grams of ozone machine for every 1 ton of finished water.

The specifications of ozone machine are 3, 5, 6, 10, 15, 20, 25, 32, 40, 50, 60, 80 g / unit.

14.UV Sterilization System

Ultraviolet is the electromagnetic wave at the wavelength of 100~380nm, which is divided into four bands according to its wavelength and function, among which UV-C is the ultraviolet band with effective bactericidal effect.

When all kinds of bacteria, viruses, parasites, algae and other pathogens in water are exposed to a certain dose of UV-C radiation, the structure of DNA or RNA in their cells is destroyed, making them lose the ability of replication and reproduction, because the life cycle of bacteria and viruses is generally very short, bacteria and viruses that can not reproduce will die quickly, so as to achieve the purpose of disinfection and purification without the use of any chemical drugs.

15.Secondary Pure Water Tank (Finished Water Tank)

Used to store product water.

There are high, medium and low water levels in the water tank; when the water level in the tank is low, the pure pump automatically stops the water supply until the water in the tank reaches the middle water level or is higher than the middle water level, and the water supply can be resumed automatically; when the water level in the water tank is lower than the middle water level, the two-stage high-pressure pump automatically starts to make water, until the high water level in the water tank, the two-stage high-pressure pump automatically stops operation.

If there are special sterilization requirements, an immersion ultraviolet sterilization device can be installed in the water tank.

16.Pure Water Pump.

Automatic delivery of pure water for water consumption points.

Control: it starts and stops automatically under the control of the water level of the pure water tank.

17.Rear Precision Filter.

As the final primary treatment of the finished water, the device mainly removes fine particles and bacterial debris.

The filter element has a folding microporous filter element and a titanium alloy filter element; the folding filter element is not resistant to ozone for a short life, and ozone water has great oxidizability to the folding microporous filter element, so it can not be used in the production line of barreled and bottled water to prevent the microporous filter element from polluting the finished water after oxidation.

The filtration accuracy is 0.22-1U.

Titanium alloy filter element has the characteristic of long life resistance to ozone, and the filter range is 0.45μ-1μ.

18.Pipe

The system can be connected by UPVC fitting pipe or stainless steel pipe.

UPVC pipe fittings have been recognized by customers for their quality, strong acid-alkali resistance and aging resistance after many years of application.

The high pressure part of the equipment with more than 2m ³/ h is connected by stainless steel fittings.

19.Control.

The system is divided into two modes: manual mode and fully automatic mode.

The automatic control system uses PLC (programmable controller) as the central control component, and realizes the automatic operation of the system through the combination of multi-point and multi-channel water level sensor and dynamic pressure controller.

Manual operation can be used for installation, debugging, maintenance or automatic system failure.

If you are looking for RO water treatment system or water purification unit, please feel free to leave your message in below form and our engineer will contact with you within 11 hrs.