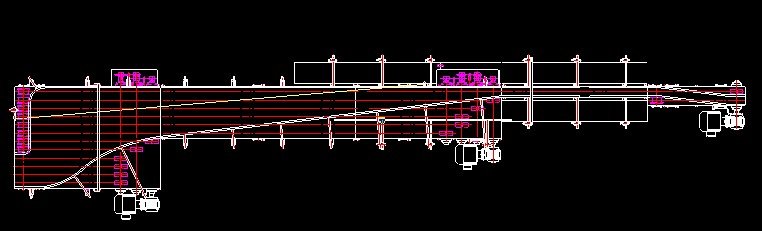

It consists of an inclined multi-column (at most 12 columns or more) three sections of conveying chain with different speeds, which is about 8 meters long and is rotated by three variable frequency speed regulating motors. It is equipped with photoelectric detection of full bottles, accumulated bottles and the number of bottles supplied (the number of bottles per unit time). According to the detected speed pulse signal, the speed of the conveying chain is automatically synchronously tracked by PLC to ensure continuous and non-overstocked bottle supply. This section is also equipped with bottle guide and bottle arrangement devices.

What is the Function of Pressure-less Conveying on the Production Line

The whole line is equipped with a set of pressure-free conveying system, which solves the problems such as bottle squeezing, bottle jam, bottle pouring, instability and reliability when changing from multi-column bottle to single-row bottle in medium and high speed bottling production line.

In the inlet section of the labeling machine, the pressure-free conveying system changes from multi-column to single-column.

The conveying is smooth, and the smooth passage between the bottles without extrusion and without sticking is realized in the single-row chain plate section.

The transmission speed is synchronized with the labeling machine by using the programmable controller and the speed regulation of the frequency converter.

Avoid pouring bottles. The speed difference of the conveyor belt adjusts the speed of the bottle, which needs to be installed and adjusted in the later stage.

If you are looking for liquid bottling line, please feel free to leave your message in below form and our engineer will contact with you within 11 hrs.