Classification of Cap Elevators and their advantages and disadvantages

1、Cap elevator & sorter

How it works: use a belt to transport the bottle cap upward, and use a protruding Radian in the picture to make the back bottle cap fall due to gravity.

Advantages: no need separate cap sorter and it is compact and quiet.The impact damage to the bottle cap is small, the bottle cap has no extrusion, and the efficiency is high.

Disadvantages: Cost is little high.

Application: 2000BPH-36000BPH production line.

2、Air Blow Type Cap Loader and Cap Sorter

Bottle cap bin-drive-transfer to the tuyere-with the help of wind through the pipe-lid remover (eddy current rotation-use of centrifugal force to manage the cap-anti-cap removal device-secondary removal device at the falling cap guide rail-the amount of the bottle cap at the lid rigger ensures that the lid does not overstock).

Advantages: high efficiency, long-distance transmission by wind power.

Disadvantages: rely on wind transmission, especially through the pipe bend, will form an impact-broken tendons or fracture, there is a certain degree of damage to the lid.

Manually deliver the bottle cap to the cap bin

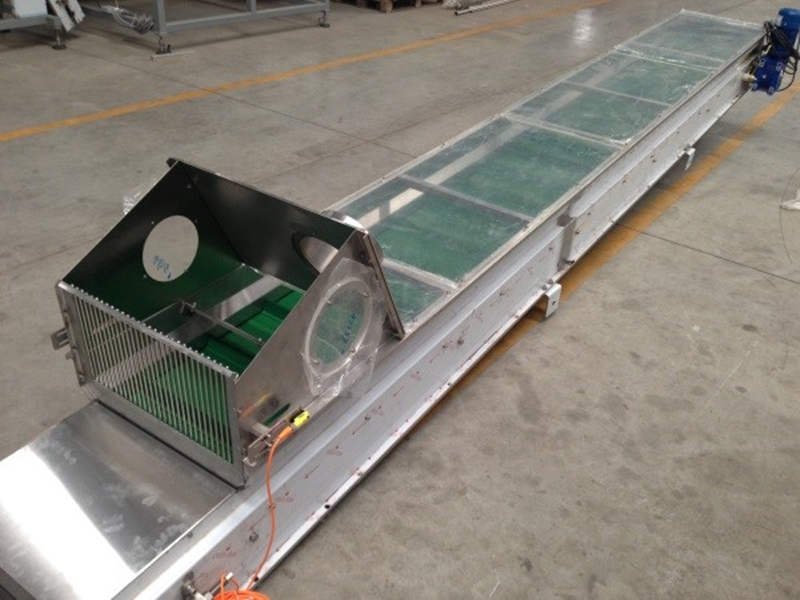

3、Belt Type Cap Elevator

Advantages: for 5-gallon bottle caps.

Sports cover-heavier.

Soy sauce lid.

The cost is higher than that of air delivery, and it is generally used for low speed.

Working principle: a certain number of bottle caps are put into the lid silo, and the cap belt motor starts and drives the swinging rod to swing at the exit of the lid silo, so that the bottle cap falls smoothly on the lid belt, and then is transmitted to the conveying air duct by the lid belt. Under the action of the wind force of the fan, the bottle cap is transmitted to the capper through the conveying pipe to achieve the purpose of conveying the cap.

The main working parts of the SGB top cover are all in the box made of stainless steel, and the appearance is simple and beautiful.

Main features:

The main results are as follows: 1) if the bottle cap in the lid bin needs to be discharged, the connecting cap plate can be flipped so that it is connected with the conveying cap belt, and the bottle cap on the conveying cap belt skips the conveying duct and slides directly into the capping plate to achieve the purpose of draining the bottle cap.

2) the conveying cover belt motor not only drives the belt running, but also drives the swinging rod to swing at the cover opening, and the conveying cover belt is equipped with a tensioning device.

3) the bottle cap transmitted from the conveying duct enters the hopper surrounded by vents to separate the air, and the bottle cap falls into the capper under the action of gravity.

4) the upper lid cover warehouse is equipped with a missing cover detection signal, and when the cover is missing, the indicator light on the box body is lit and the alarm is given.

Advantages:

(1) stable performance.

(2) the upper cover device is equipped with a missing cover detection system, and the box indicator light is lit when the cover is missing.

(3) the cover is arranged by high efficiency centrifugal type, and the wear of the cover is small.

(4) there is a bottle cap testing mechanism to control the start and stop of the upper cap device.

(5) the falling cover guide rail of the lid device is provided with a mechanism to prevent the reverse cover from passing through and taking out the reverse cover.

If you are looking for Bottle Water Filling Machine, please feel free to leave your message in below form and our engineer will contact with you within 11 hrs.