Details About 10000BPH(600ml) Auto Water Bottle Filling Machine CGF24-24-8

More and more customers want to produce bottled water. And most of them are the first time to do water business, they have no idea what’s the capacity to start with. As our experience, 10000 bottle per hour is an ideal capacity for the first trial. This capacity filling line is not very expensive, and most investors can afford it. 10000BPH water bottle filling machine is the main machine in this line. If you want to import water bottle filling machine from China, then Festa will be the best choice.

Festa is a leading water filling machine manufacturer, all of our PET bottle filling machine can meet and exceed national standards. We will also provide a competitive price for your filling project. With professional team and technical support, Festa will give you the best filling solution based on your project requirements.

Drop us an email or fill out below form to send us an order now!

10000BPH(600ml) water bottle filling machine

1) Rinsing part

- Except the down framework, the transmission parts and some parts that must be made of special materials. Other spare parts are made of stainless steel 304.

- The roller bearing is made of stainless steel, the sealing ring is made of EPDM material, and plastic is made of UMPE.

- The gripper is made of stainless steel, the position where hold the bottleneck is also made of stainless steel, compared with the traditional rubber gripper, it is much hygiene, durable, and no quick-wear parts, the screw parts of the bottleneck can avoid being polluted by the rubber gripper.

- The gripper equipped with high-efficient spray nozzle, it can develop to any position of inside of the bottle, and can save rinsing water. There is a cover above the spray nozzle which can prevent water spilling; and there are regulatory recycle slot and recycle pipes under the nozzles.

- Rinsing time can be guaranteed for 4 seconds.

- By adjusting the height of the rotary parts to adapt for different bottle height

- The supplying of rinsing water is controlled by solenoid valve.

2) Filling part

- Adopted Germany igus anti-corrosion non-maintaining bearing that can reduce the pollution of filling to the environment.

- The rotate plate is made of SUS AISI304, large flat toothed bearing.

- The pressure mechanical valve is introduced the advanced foreign design with a fast filling speed, no hygiene corner pocket, a few sealing parts, and precise liquid level control. The whole valve is made of 316L stainless steel.

- The filling system has a CIP circulation system to wash the pipeline and fake-cup used for cleaning filling valve. This system can clean the juice pipe, liquid tank and filling valve etc. effectively.

- The juice supply adopts the automatic pneumatic valve magnetic liquid-level switch to control the liquid tank automatically.

- Sliding bearing is adopted Germany igus anti-corrosion non-maintaining bearing, that can reduce the pollution of filling to the environment. Rolling bearing made of stainless steel, the sealing ring is made of EPDM material, plastics is made of UMPE.

3) Capping part

- The device which can take out the reverse cap and prevent the reverse cap passing is settled in the cap-falling guide.

- A group of photoelectric switches are settled on cap-falling guide. The machine will stop when there is no cap on the guide.

- A bottle inlet detect switch is settled on the screwing capper.

- There are aseptic nozzles between the transition poking wheel and filling parts to rinse the product rested in the bottleneck screw parts.

- By adjusting the height of the rotary parts to adapt for different bottle height.

- The motivation of the screwing capper is derived from the driven system in the framework and passed by gear.

- The main parts of the screwing capper are processed by the digital-control processing center

| Model | Rinsing heads | Filling heads | Capping heads | Production Capacity | Machine Power | Weight | Dimension(mm) |

| XGF12-12-6 | 12 | 12 | 6 | 4000-5000BPH | 3kw | 3200kg | 2500*1880*2300 |

| XGF18-18-6 | 18 | 18 | 6 | 6000-8000BPH | 3kw | 4500kg | 2800*2150*2300 |

| XGF24-24-6 | 24 | 24 | 8 | 10000-12000BPH | 5kw | 6500kg | 3100*2450*2300 |

| XGF32-32-8 | 32 | 32 | 10 | 13000-15000BPH | 6kw | 7500kg | 3680*2800*2500 |

| XGF40-40-10 | 40 | 40 | 12 | 16000-18000BPH | 9kw | 9500kg | 4500*3200*2700 |

| XGF50-50-12 | 50 | 50 | 15 | 20000-22000BPH | 11kw | 13000kg | 5200*3700*2900 |

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

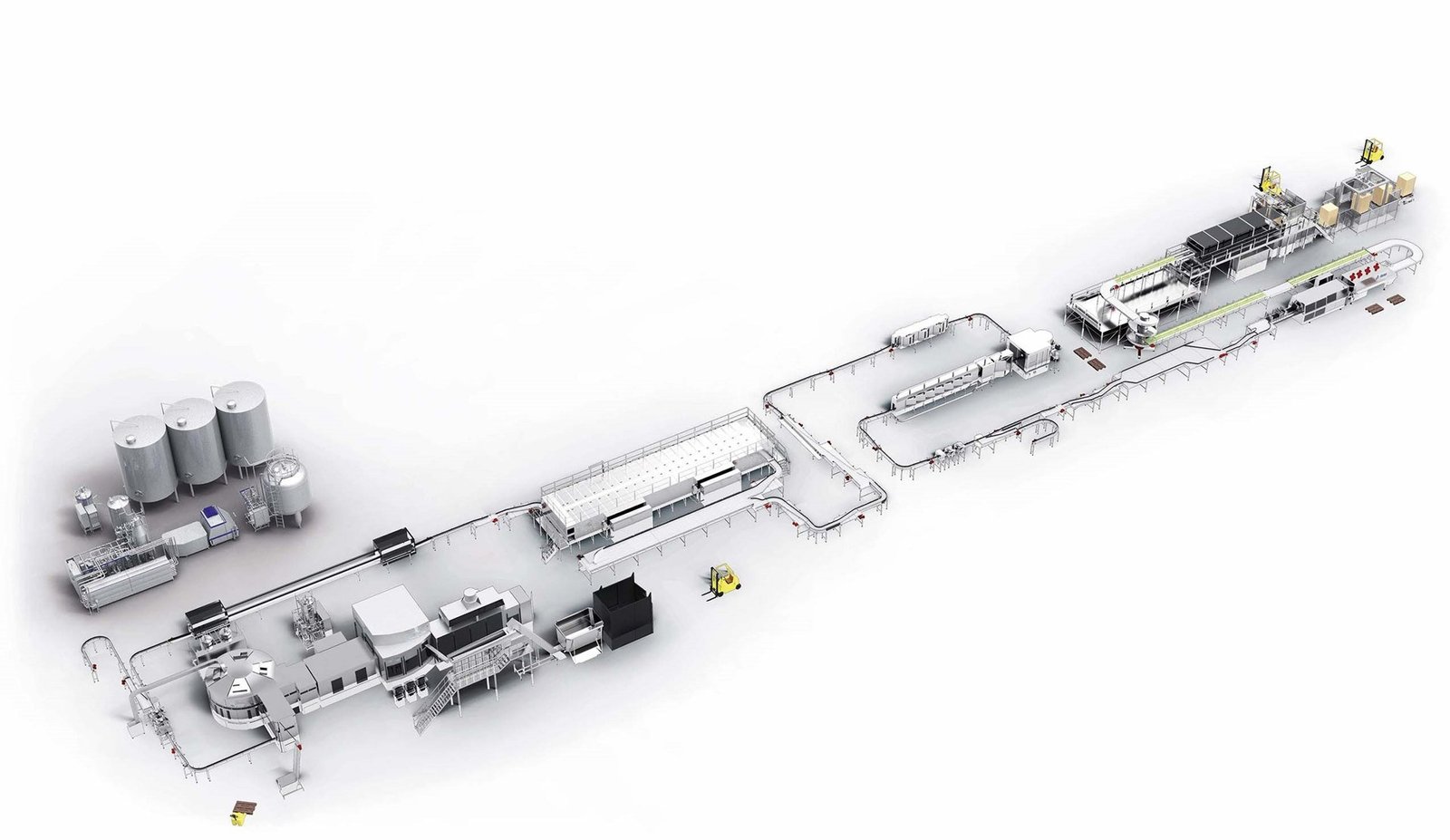

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.