18000BPH Bottling Machine Washing Filling Capping XGFH40-40-10

18000BPH(420ml) Drinking Water Bottling Machine Water Filler XGFH40/40/10

- Model: XGFH40/40/10 washing filling capping monoblock

- Production capacity: 18,000 bottles per hour

- Main material: SUS304

- Mitsubishi PLC or equivalent brand

- HMI: Pro-face Japan

Details About 18000BPH Bottling Machine Washing Filling Capping XGFH40-40-10

Festa 18000BPH water bottling machine consist of separate washing, filling, and capping units.

It is in the introduction, digestion, absorption of Germany, Italy advanced technology on the basis of pure water and large bottles of mineral water requirements for innovative design.

It can be used to bottle from 250ml to 2000ml bottled still water, pure water, reverse osmosis water, mineral water, soda, etc. .

Main features.

Bottle Washing Unit:

In the process of bottle washing, the spring steel griper will hold the PET empty bottle, and under the clamp, the empty bottle will be turned 180 °along the track to make the bottom of the bottle upward.

The bottle washing machine can wash the inner and outer surface of the bottle at the same time through the high-pressure nozzle, so the cleaning efficiency is higher.

The bottle washing machine adopts the double opening steel griper created by FESTA.

The steel griper is made of S/S304, which is sanitary and durable.

The steel griper is equipped with high efficiency nozzle.

High-pressure water is ejected from a special angle to flush, which ensures the cleanliness of the bottle and high water-saving efficiency.

Bottle Filling Unit.

The structure of the filling machine is compact, the flow rate of the filling valve is fast and there is no sanitary dead corner.

The filling equipment has high stability in long-term operation, and the filling liquid level can be controlled according to the requirements of the factory, and the control precision is ±2 mm.

The filling valve is made of food grade stainless steel 304, and the filling system is equipped with automatic liquid level control function.

The opening and closing of the filling valve are automatically controlled by the machine, and the filling procedure is not carried out in the station without bottles.

When the bottle enters the filling machine through the star wheel, the bottle rises to a certain height under the action of the cam of the filling machine, and the bottle mouth presses the filling valve, which opens automatically and starts water filling.

The filling process stops automatically when the filling liquid level reaches the set liquid level, ensuring that the capacity of each bottle of water is constant.

Bottle Capping Unit.

The full-automatic bottled water capping machine is the component with the highest precision in the whole equipment, and the quality of the cappingc machine will affect the stability and defective rate of the product to a great extent.

Characteristics of FESTA sealing machine.

1) Adopt the best capping machine technology in the world, combined with many years of industry experience of FESTA, constantly improve the accuracy and operation stability of the sealing machine.

The capping head is sealed with magnetic constant torque, and the capping torque can be adjusted stepless according to the condition of the cover. It has better adaptability to the lid of different quality, the cover loss rate is low, and the sealing process is reliable.

2) Install the photoelectric controller on the sealing machine, when the lid breaks, the machine will automatically alarm and stop.

Equipment Parameter

| Model | XGFH40-40-10 | |

| Working Station | Washing 40 Filling 40 Capping 10 | |

| Production Capacity | 18,000 bottles per hour | |

| Suitable Bottle | Diameter | 55~110mm |

| Height | 186~310mm | |

| Air Pressure | 0.7MPa | |

| Air Consumption | 0.8 m3/min | |

| Washing Pressure | 0.2~0.25MPa | |

| Washing Consumption | 2.5ton/hr | |

| Voltage | 380V | |

| Control Voltage | 24V | |

| Power | 5.5kw | |

| Dimension | 4110X2740X2700 | |

| Weight | 9000kg | |

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

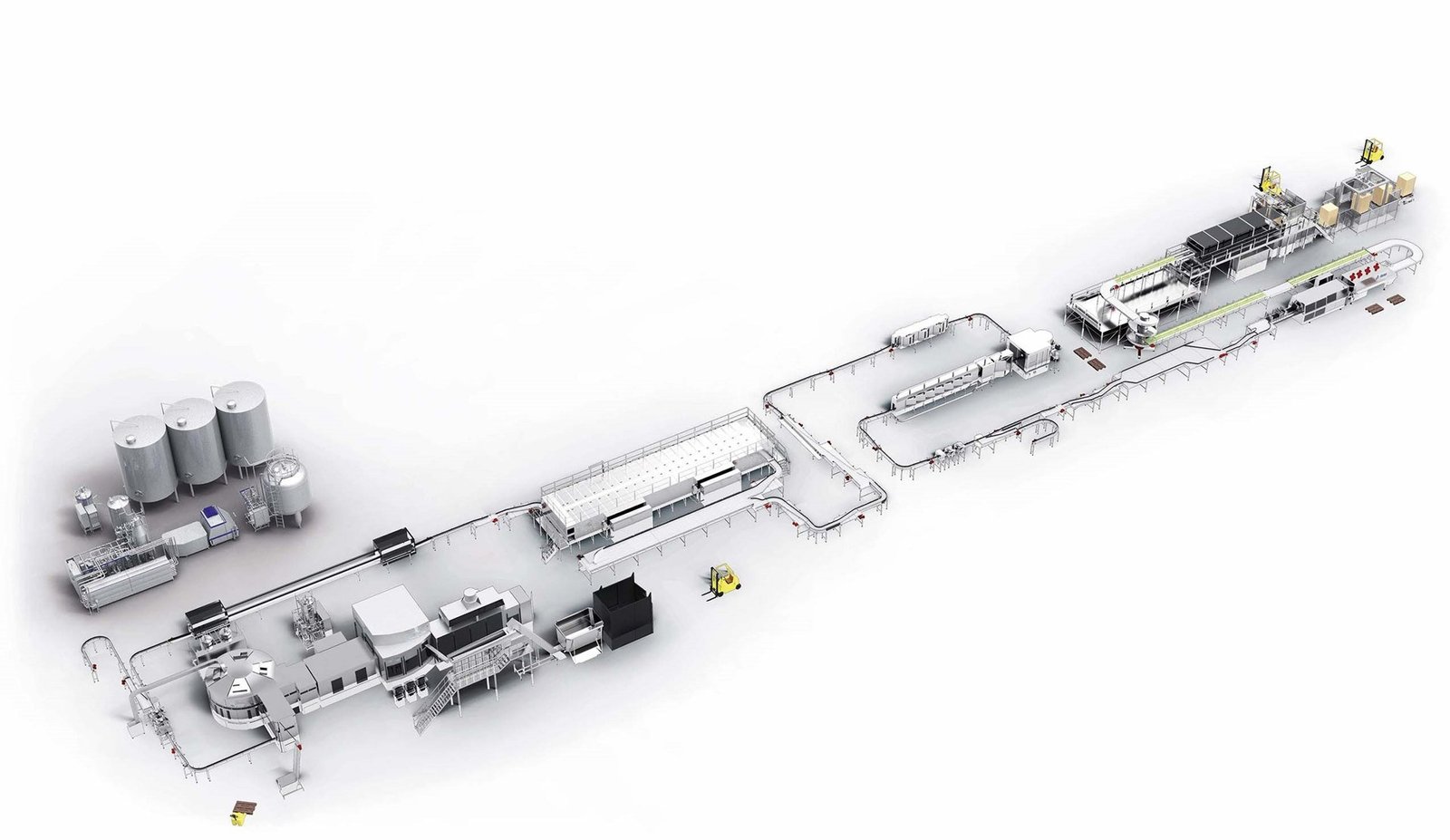

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.