Ultra clean medium temperature liquid dairy juice filling machine

We supply Ultra Clean Filling Machines Rinser/Filler/cappers for filling of delicate products such as fresh pasteurised milk, fruit juices, pharmaceutical products. We have developed a hygiene filling valve which simplify the cleaning process. The machines can be built with traditional bottle transfer methods or Neck Handling for PET bottles.

Details About Ultra clean medium temperature liquid dairy juice filling machine

The process for Ultraclean filling is as follows:

A) Chemical sterilisation of the bottles

B)Bottle sterile rinsing using disinfectant and combined with sterile water rinsing of the Auxonia

C)Ultra Clean Sterile filling valve

D)UV ray chemical sterilisation of the caps washing with sterile water before capping in clean room. the bottle disinfectant or caps can be sterilesd with steam in the chute or by an disinfectant spray.

E)Over pressure in the filling machine with sterile filtered air is vital to ensure harmful bacteria are filtered out of the air inside the filler. Air is first filtered via an HEPA filter and poumped at a light pressure inside the filter which is enclosed in a full shell where air is filtered. the overpressure ensures that no contaminated air is let in the filling machine during normal production.

Ultra Clean Filling is a process concept involving the combination of various technologies rather than a single “filling machine” techncal item. The process involves also an “environment” element that isit requires a production attitude to clean filling processes in the staff of the factory.

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

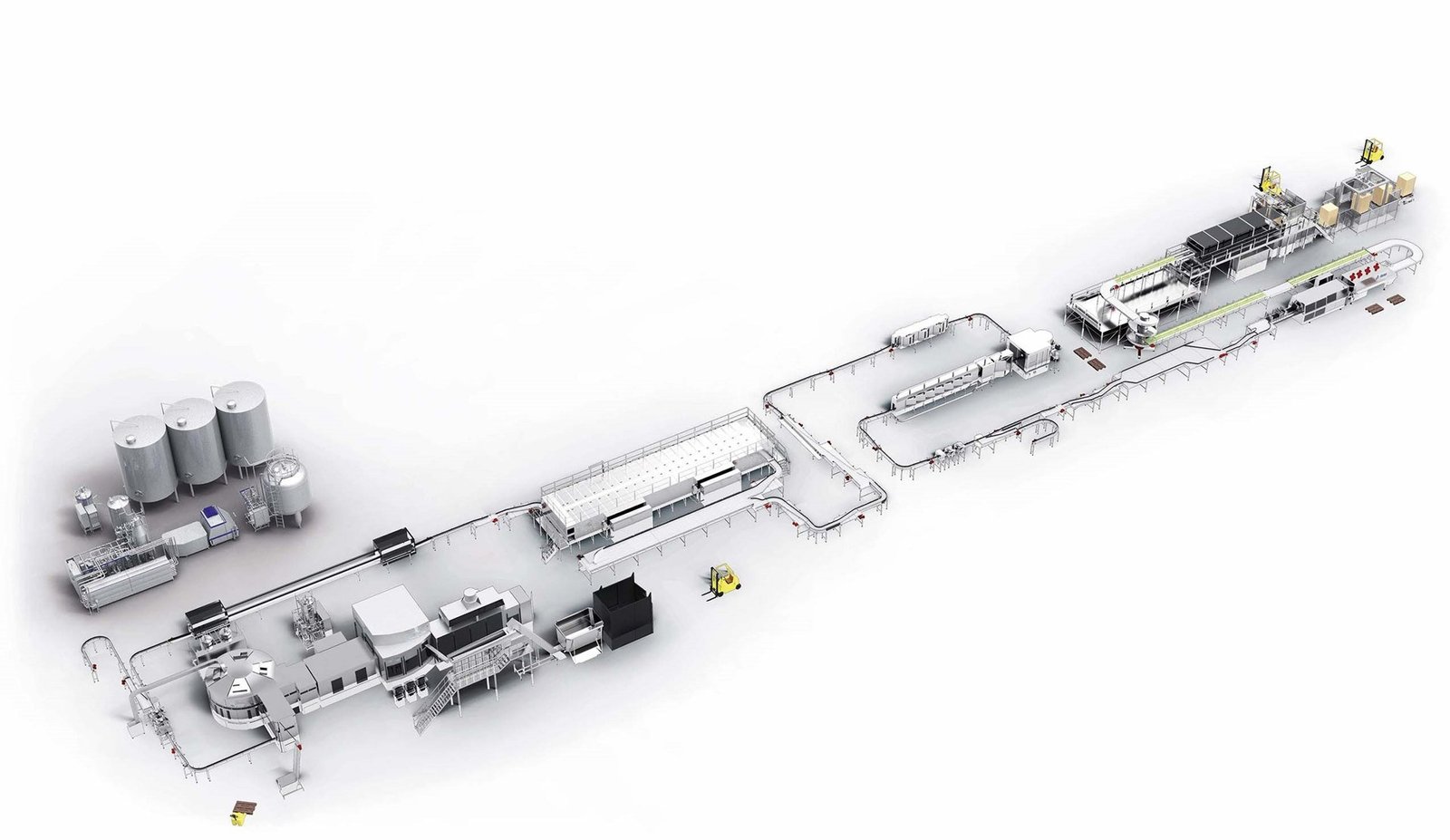

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.