Details About Ultra Clean Filling Machine Price Bottle Filler Juice Bottling Machine For Sale

If you are looking for this high production capacity ultra clean filling machine price, please fill out below form, we will contact you within 8 hours.

FESTA XXGF60-60-40-15 water bottling filler machine uses the air conveyor to feed the bottle, and the bottle mouth holding technology is used in the whole process

The whole machine consists of the following parts.

Frame and window.

Main transmission assembly.

Filling assembly.

Bottle transmission system.

Gas path system.

Electric system.

Bottle capping assembly.

Bottle washing assembly.

Disinfectant bottle washing assembly.

Centralized lubrication system.

The bottles are transmitted through the air conveyor and through the feeding star wheel to the first disinfectant bottle washing machine. The bottle washing machine is equipped with bottle gripper. The bottle gripper holds the bottle mouth and flips 180 ° along the guide rail to make the bottle mouth downward. In the specific area of the bottle washing machine, the bottle washing nozzle ejects water with a certain pressure to wash the inner wall of the bottle. After washing and draining, the bottle is turned 180 ° along the guide rail to make the mouth of the bottle upward.

The washed bottle is exported by the first disinfectant bottle washing machine through the star wheel and transferred to the second bottle washing machine. After repeating the first bottle washing process, it is transmitted to the water filling machine through the transmission star wheel, and the bottle entering the filling machine is stuck by the lifting device, and under the action of the lifting cam, the bottle rises and contacts and presses and opens the filling valve to start filling, when the liquid level reaches the height of the air back pipe, the filling is stopped automatically, and there is a rotating handle mechanism at the top of the cylinder, which can be switched between filling and pumping to ensure that the filling level is basically consistent. After the filling is finished, the lifting device drops under the action of the press-down cam to make the filled bottle leave the filling valve, and the filling ends. The bottle enters the capping machine through the transition star wheel. The card board and anti-rotate knife on the capping machine hold the bottle, and the nylon plucking wheel protects the bottle and keeps the bottle upright.

The cover is arranged by the upper cover device and enters the capping machine through the falling cover guide rail, and the capping head realizes the whole sealing process under the action of the cam.

The bottled water after filling and sealing is transferred from the capping machine to the solid bottle conveying chain through the bottle star wheel, and the four-in-one filling machine is transmitted by the solid bottle conveying chain.

The bottle mouth clamping method is adopted in the whole process to avoid the secondary pollution in the production process of bottled water.

Safety device.

Operators should be familiar with all safety devices and how to use them to avoid personal injury and machine damage.

A quick stop switch is arranged on the machine.

Bottle Water Machine Parameter

| Model | XXGF60-60-40-15 | |

| Working station | Disinfectant wshing 60

Clean water washing 60 Filling 40 Capping15 |

|

| Production capacity | 24000BPH(500ml) | |

| Bottle size | Diameter | 45~90mm |

| Height | 150~300mm | |

| Air pressure | 0.8MPa | |

| Air consumption | 0.3 m3/min | |

| Disinfectant washing pressure | 0.2~0.25MPa | |

| Disinfectant consumption | Recycle use | |

| Washing presure | 0.2~0.25MPa | |

| Washing water consumption | 2500kg per hour | |

| Main power | 11kw | |

| Dimension | 7660X3400X3350 | |

| Weight | 15000kg | |

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

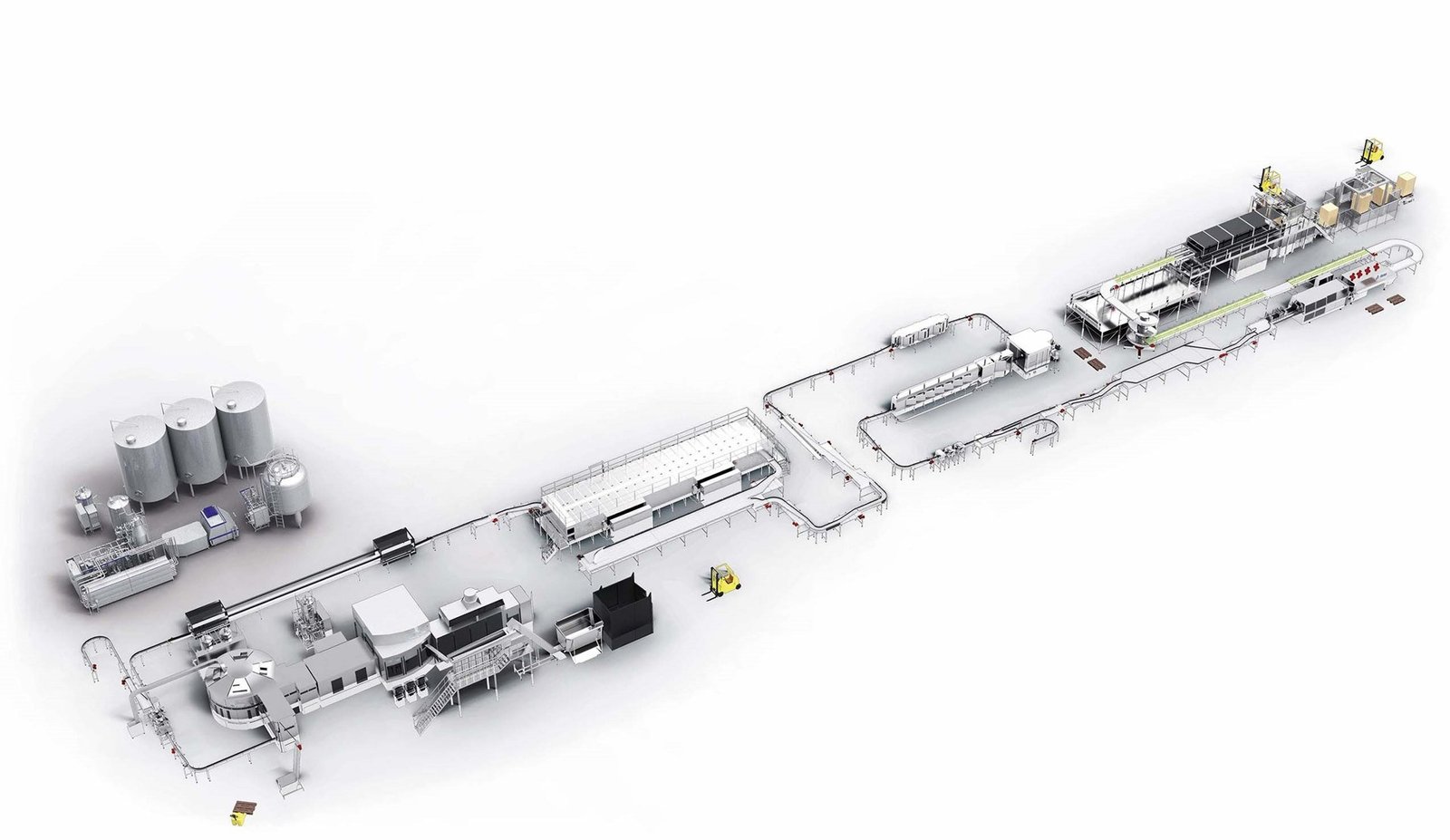

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.